Fascination About Steel Road Plates

Wiki Article

Steel Road Plates Can Be Fun For Anyone

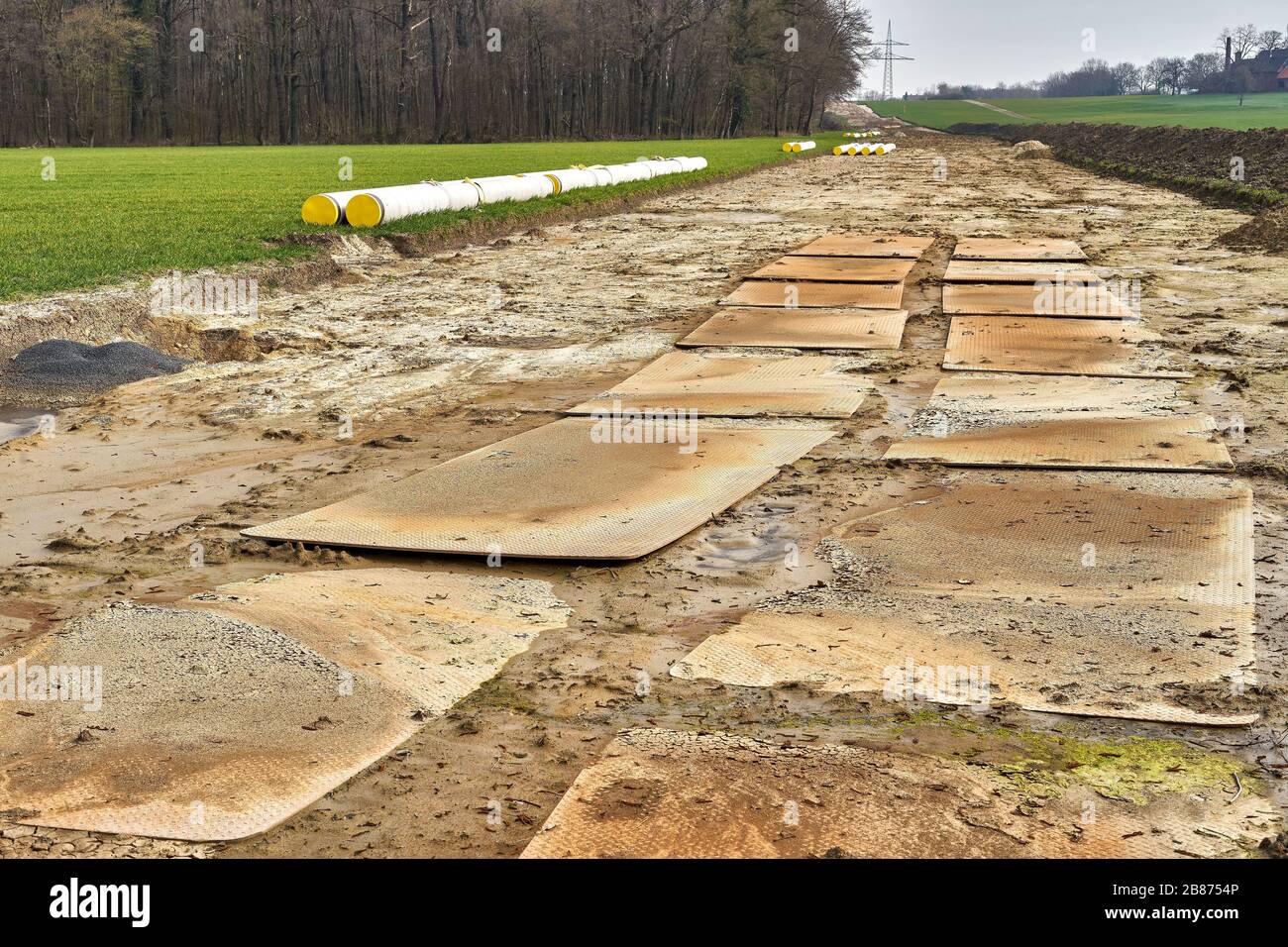

These sturdy, robust plates permit roads to return to service so that building and construction can continue. These plates can be used to make sure that roadways can still be used whilst other stages of job proceed.They are usually seen when excavations have begun as an early stage of construction or repair service jobs. These plates are created to withstand durable usage on hectic roads.

The weights begin from around 300kg and typical road plates have a density of either inch or inch. The ability to be bolted to the road.

About Steel Road Plates

Hinged versions for fast access to the excavation or routine gain access to, e.g. driveways. Compound plates, which can accommodate numerous sizes of trench. Skid-resistance for enhanced vehicle, pedestrian and website worker safety. Steel roadway plates can be set up relatively quickly, yet they are heavy. Therefore, they must be installed utilizing a forklift or crane.Look for variation by website traffic packing from the start plates should constantly resist displacement. Check that the plates do not offer a danger to any kind of roadway individual and can be made use of by all roadway individuals and vehicle kinds, including pedestrians, bikers and motorcyclists. Create a routine evaluation and upkeep to ensure that efficiency remains risk-free and optimal.

Take care of the plates correctly at all times. Mechanical training makes sure that the plates are installed precisely and safely.

If a ramp is created by the road layers, after that alerting indications for pedestrian and road users are required. Constantly a conduct full website study, and take the expert guidance of a structural designer.

Fascination About Steel Road Plates

In order to improve safety and security, there are a number of requirements and industry view publisher site files guiding their use in building job areas. Steel plates should be dealt with in area to stay clear of movement.

All About Steel Road Plates

Along with being securely in call with the pavement, they should be either pinned, recessed right into the pavement, or safeguarded with asphalt wedges around the border. Pinning into the sidewalk entails driving pins right into the sidewalks along the edges of the steel plates to avoid movement. Recessing includes cutting out the area where the steel plate will be put.

This results in the steel plate being flush with the pavement. In addition, when numerous steel click to investigate plates are used and butt up to each various other, they should be welded with each other at the longitudinal seams. Steel plates can be very unsafe, specifically when they are damp, unless they have an anti-skid finish used.

Covering steel layers with a product that enhances rubbing helps motorcyclists and bicyclists preserve control, specifically in damp weather. Problems which decrease sidewalk rubbing in work areas are of particular problem to motorcyclists and bicycles. An usual threat in steel plate setups occurs when the customer fails to create appropriately tapered ramps from the highway to the sides of the steel plate( s).

Getting The Steel Road Plates To Work

It poses a substantial risk to motorcyclists and bicyclists that can conveniently blow up when they speak to the abrupt/steep tapered ramp and the steel plate. Properly tapered ramps permit users to safely go across over the steel plates. Tapers for steel plates are normally constructed of asphalt. The taper sizes vary from State to State and generally range from 20 to 1 to 120 to 1 (Steel road plates).Division of Transport's Federal Freeway Management (FHWA) calls for that transverse sidewalk joints, which result published here in a bump, need to be tapered at 60 to 1 (5 feet straight for each 1 inch of vertical elevation difference). Select the right dimension. Make certain adequate overlap. Normally, steel plates should prolong at the very least one foot beyond the pavement opening onto company ground.

Some Of Steel Road Plates

Welding is made use of when even more than one steel plate is utilized and they butt up to each various other. Plates should be countersunk when essential due to irregular streets.

His history consists of the building and construction, evaluation, find out more.

Worldwide of civil engineering and construction, steel road layers are a quintessential tool that holds tremendous importance. These durable steel plates play a crucial function in enhancing construction security, offering temporary roads, and ensuring smooth operations on various job websites. As a building and construction equipment vendor, their significance can not be overemphasized.

Report this wiki page